Understand SSCC: sulfide stress corrosion cracking

Author:走进特钢 Date:2025-04-03 Browse Volume:133 timesSulphide Stress Corrosion Cracking (SSCC) is a major problem in metal installations and pipelines in the oil, gas and other

energy industries. Today, let's talk about SSCC in depth.

I. What is SSCC?

SSCC refers to the brittle fracture of metal materials subjected to tensile stress in sulfide media due to the coupling effect of

medium and stress. Simply put, in an acidic and sulphide environment, metal materials are prone to sudden rupture when

subjected to a certain tension. It is different from the general stress corrosion, the general stress corrosion is mainly dissolved

in the anode, and SSCC is mainly filled with hydrogen in the cathode, which is currently believed to be caused by hydrogen

embrittlement.

II. the characteristics of SSCC

After the occurrence of SSCC in oil and natural gas long distance pipelines, there are these obvious characteristics:

1. Low pressure fracture: the pipeline will break under much lower than the expected working pressure.

2. Short-term damage: When the material is exposed to a specific environment, damage will occur within a short period of

time (1 week to 3 months is more common).

3. Brittle fracture characteristics: the pipe is brittle and the fracture is flat.

4. Corrosion products: The pipe fracture is obviously covered with hydrogen sulfide (H2S) corrosion products.

5. Cracking location: often located in stress concentration points, mechanical scars, etched holes, etched pits, weld defects,

welding heat affected zone and other weak parts.

6. Crack shape: the crack is thick, the branch is less, most of it is transgranular, there are also intergranular or mixed type.

7. Material sensitivity: high-strength, high-hardness materials are very sensitive to SSCC.

8. Difficult to predict: the occurrence of SSCC is often difficult to predict in advance, and accidents are often sudden.

III. Environmental factors affecting SSCC

1. H2S concentration: The higher the concentration of H2S, the stronger the sensitivity of SSCC, and the sensitivity reaches

the strongest in saturated H2S solution. For materials of the same strength and hardness, with the increase of H2S concentration,

the time required for rupture is shortened, and the critical stress value is reduced.

2. Water content: water is a necessary condition for electrochemical corrosion, whether it is H2S in the gas phase or the liquid

phase, it is inseparable from water to cause corrosion hazards to the pipeline.

3. Temperature: In the range of 20-40 ℃ at normal temperature, the amount of hydrogen inhaled by metal is the highest, and the

possibility of SSCC is the highest; When the temperature is higher than 70℃, the sensitivity decreases. At normal temperature, the

pipe may break within 1-2 hours.

4. pH value: With the increase of pH value of corrosive medium, the stability of steel in H2S is enhanced, and the time required for

fracture is increased.

5. Other components in the medium: in H2S aqueous solution, Cl⁻ and O₂ have a greater impact on SSCC. In a certain range, the

presence of O₂ will accelerate the corrosion rate; When the concentration of Cl⁻ is higher, the corrosion rate slows down. Studies

have shown that O₂ can greatly promote SSCC.

IV. Measures to deal with SSCC

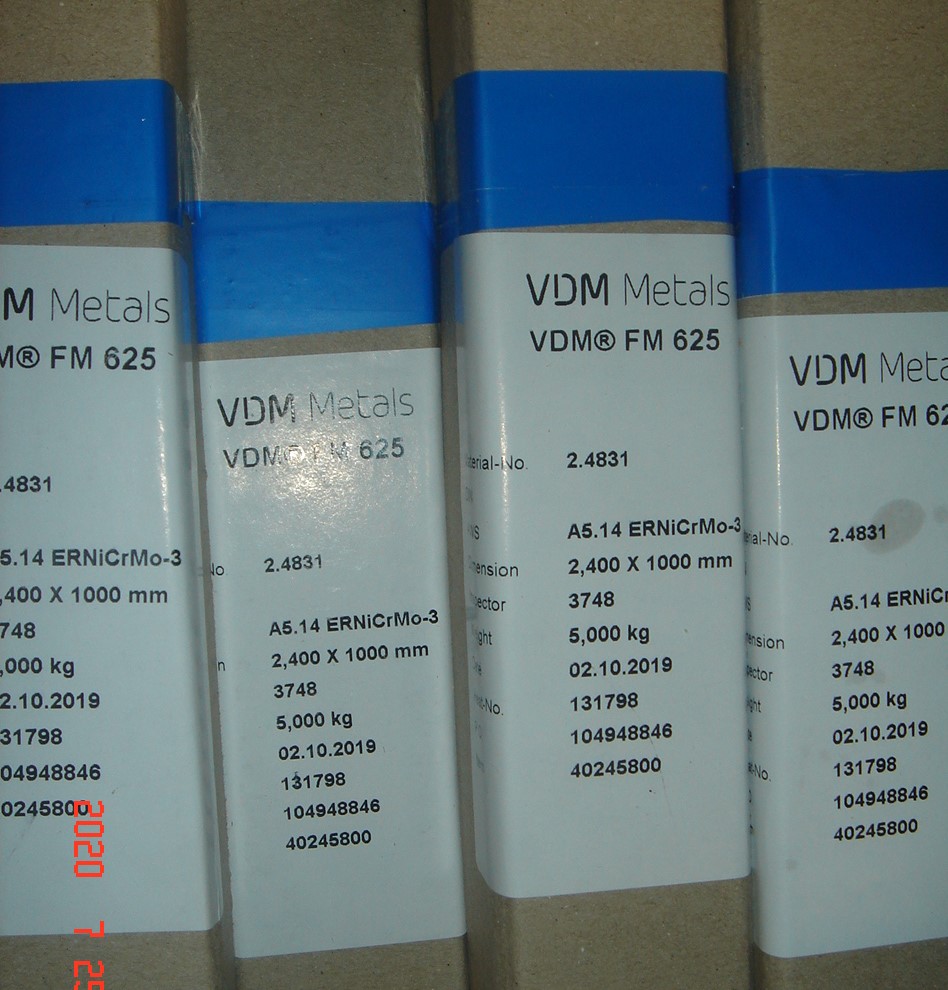

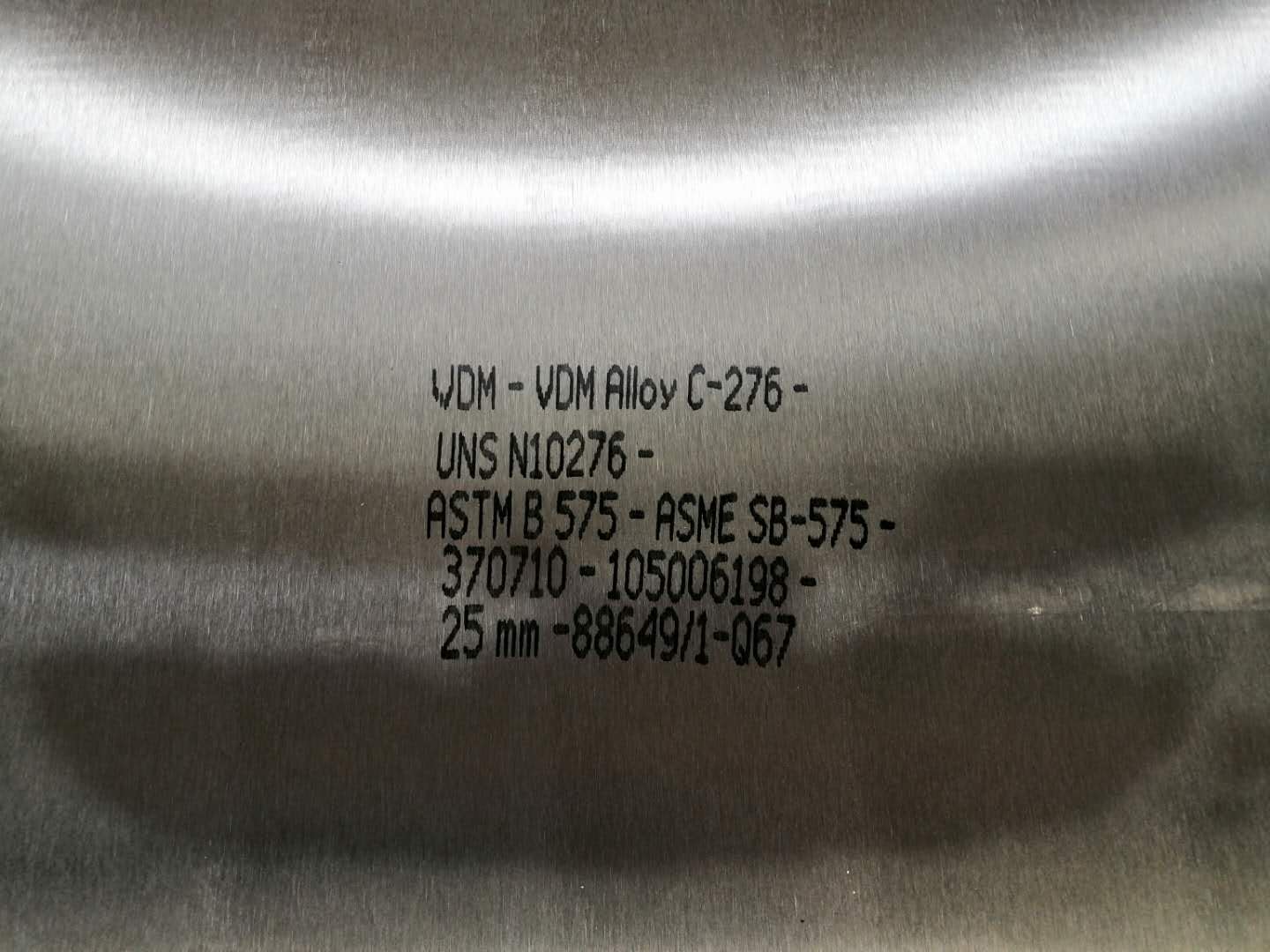

1. Material selection: Select metal materials with good SSCC resistance, such as some nickel-based alloys, low alloy steel, etc.,

to reduce the risk of SSCC from the source. Like Inconel 625 and Incoloy 825, they are resistant to corrosion and cracking in acidic

environments containing hydrogen sulfide.

2. Process optimization: In the process of pipeline manufacturing and installation,

optimize welding and processing technology to reduce stress concentration points and reduce residual stress.

3. Environmental control: where possible, control factors such as H2S concentration and water content in the medium, such as

desulfurization treatment and drying treatment.

4. Anti-corrosion measures: The use of coating, lining and other anti-corrosion means to isolate metal materials and corrosive media

contact.

SSCC poses a huge threat to metal facilities in the oil, gas and other industries. To understand its principle, characteristics and

influencing factors and take effective countermeasures, we can ensure the safe and stable operation of relevant facilities and reduce

safety accidents and economic losses caused by corrosion cracking. I hope today's sharing will give you a more comprehensive

understanding of SSCC!

The differences between genuine imported products and domestically produced narrow metal-rolled strips.

Next:Full analysis of nickel-based alloy family