Full analysis of nickel-based alloy family

Author:走进特钢 Date:2025-03-21 Browse Volume:150 timesIn the field of high - end equipment manufacturing, nickel - based alloys have become the preferred materials for industries such as aerospace, energy, and chemical engineering due to their unique high - temperature properties and corrosion resistance. The family of nickel - based alloys is large, and different series and grades have their own advantages. This article will systematically sort out their classification and characteristics, taking you to have an in - depth understanding of the full - range of products.

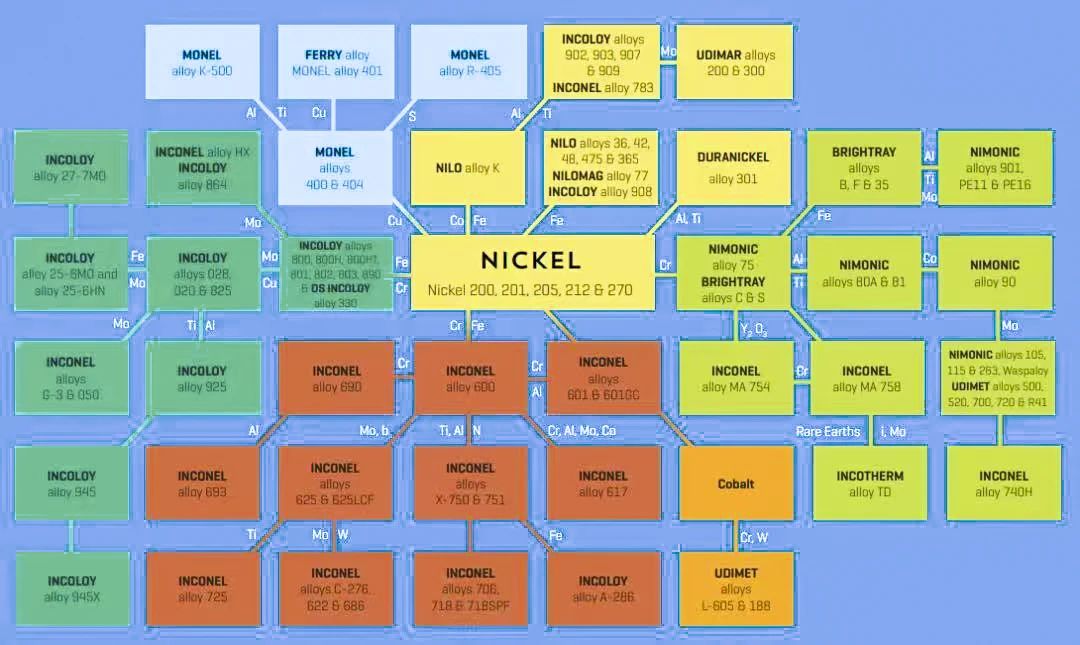

1. INCONEL Series - The "Performance Star" with High - temperature Strength and Toughness

The INCONEL series is a star family among nickel - based alloys, renowned for its excellent high - temperature strength, oxidation resistance, and corrosion resistance, and is widely used in extreme working conditions.

INCONEL 600 is a classic nickel - chromium alloy with a chromium content of approximately 15%. In a high - temperature environment, it forms a dense chromium oxide layer to resist oxidation and carburization. It is resistant to corrosion by nitric acid, acetic acid, etc., and is often used in heat treatment baskets for chemical equipment and components of nuclear power steam generators.

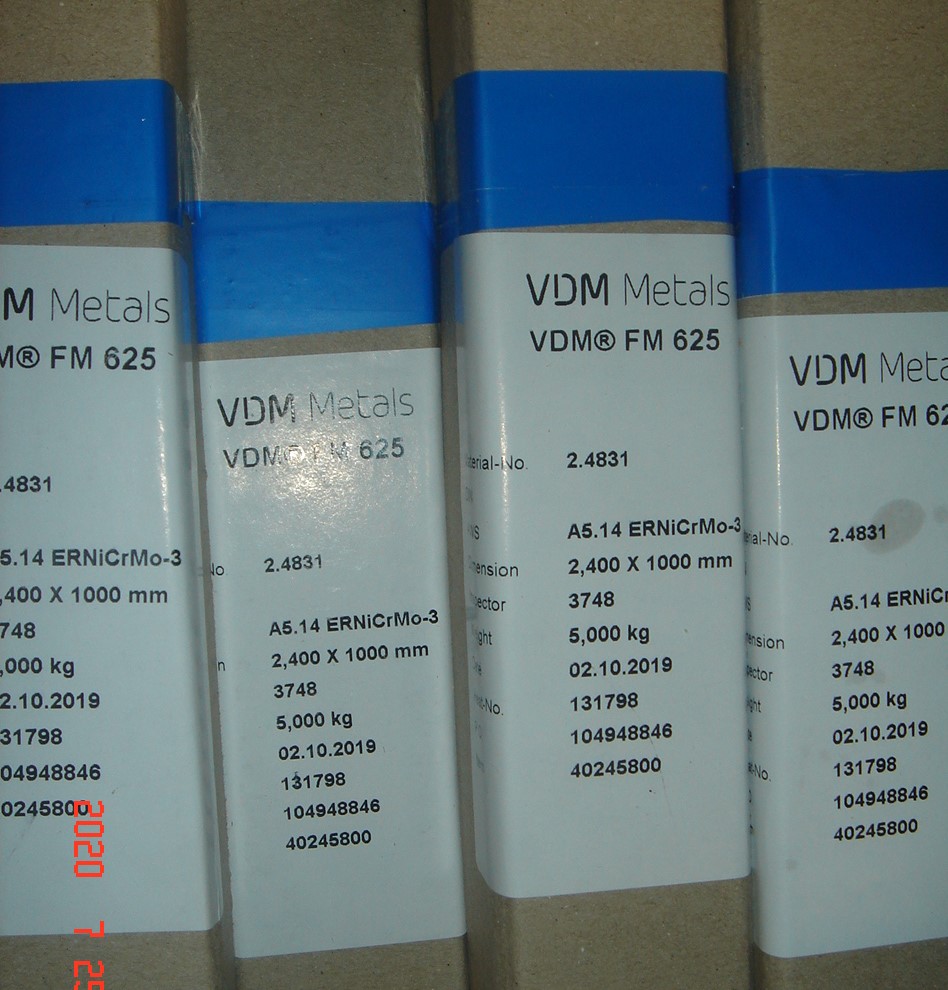

INCONEL 625 incorporates molybdenum and niobium elements, which enhance its high - temperature strength through precipitation strengthening and can obtain high toughness without heat treatment. It performs excellently in marine environments and components of gas turbine combustion chambers, and is especially suitable for welded structures, such as deep - sea pipeline connectors.

INCONEL 718 is a precipitation - hardening nickel - based alloy containing elements such as niobium, aluminum, and titanium. It can maintain high strength in a wide temperature range from - 253°C to 700°C and has outstanding fatigue resistance. It is the core material for turbine disks of aero engines and fasteners of rocket engines.

INCONEL 690 has a high chromium content (approximately 30%) and excellent intergranular corrosion resistance. It has strong tolerance to high - temperature and high - pressure water environments and is specifically used for heat transfer tubes of steam generators in nuclear power plants to ensure the long - term safe operation of nuclear facilities. 2. INCOLOY Series - The "Versatile Player" in Corrosion Resistance and High - temperature Oxidation

The INCOLOY series focuses on comprehensive corrosion resistance and high - temperature oxidation performance, adapting to diverse industrial scenarios.

INCOLOY 800/800H is an iron - nickel - chromium - based alloy. Chromium and aluminum elements endow it with high - temperature oxidation resistance, and it resists carburization and sulfidation below 800°C. It is often used for heating furnace tubes in the petrochemical industry, conveyor belts of heat treatment furnaces, and can also be used to manufacture components of waste gas treatment devices.

INCOLOY 925 adds copper, aluminum, and titanium, combining corrosion resistance and strength. It has excellent stress corrosion cracking resistance in acidic environments containing chlorides and is an ideal material for oil and gas pipelines and downhole tools in oil and gas extraction, dealing with highly corrosive reservoir environments.

INCOLOY 25 - 6MO has strong tolerance to corrosive media such as chlorides, sulfuric acid, and phosphoric acid, especially resistance to pitting corrosion and crevice corrosion. It is suitable for seawater desalination equipment and chemical reaction kettles and plays a key role in marine engineering and pharmaceutical equipment. 3. MONEL Series - The "Marine Guardian" Resistant to Seawater Corrosion

The MONEL series is based on nickel - copper alloys and performs outstandingly in environments containing chloride ions. MONEL 400 is a nickel - copper binary alloy with a copper content of approximately 30%. It has good corrosion resistance to seawater, hydrochloric acid, and hydrofluoric acid. In the shipbuilding industry, it is used to manufacture seawater pipelines and valves; in the chemical field, it is suitable for hydrochloric acid transportation equipment, such as evaporators and reaction vessels.

MONEL K - 500 adds aluminum and titanium on the basis of MONEL 400 and enhances its hardness and strength through aging strengthening. It not only maintains the characteristic of seawater corrosion resistance but also has higher mechanical properties. It is commonly used as ship pump shafts and sealing rings in the petrochemical industry to deal with high - load corrosive working conditions. 4. Other Characteristic Series - The "Specialized Players" in Niche Fields

NIMONIC Series: For example, NIMONIC 90 contains cobalt and chromium elements and has excellent high - temperature creep strength. It is a special material for high - temperature components (such as blades and springs) of aero engines and can still maintain stable performance in an environment of 900°C.

NILO Series: It is a representative of low - expansion alloys. For example, NILO K has an extremely low coefficient of thermal expansion and is used to manufacture parts of precision measuring instruments and packaging materials for electronic devices to ensure dimensional accuracy under temperature changes.

UDIMET Series: Taking UDIMET 720 as an example, it adds a variety of alloy elements to enhance high - temperature strength and fatigue resistance and is mainly applied to high - performance components of aero engines to meet the reliability requirements under extreme working conditions. The nickel - based alloy family, through the composition design of different series, has constructed a material matrix covering the needs of high temperature, corrosion resistance, precision, etc. From aerospace to marine engineering, from energy and chemical engineering to precision instruments, each grade plays an irreplaceable role in its respective niche field. As the manufacturing industry moves towards high - end development, nickel - based alloys will continue to iterate and innovate, continuously providing material support for advanced equipment. Follow us to obtain in - depth analysis of more metal material technologies and explore the infinite possibilities of industrial materials!

The differences between genuine imported products and domestically produced narrow metal-rolled strips.

Next:Key Points for the Precise Selection of Nickel-based Alloys