How can we save one ton of carbon emissions with just one gram of alloy?

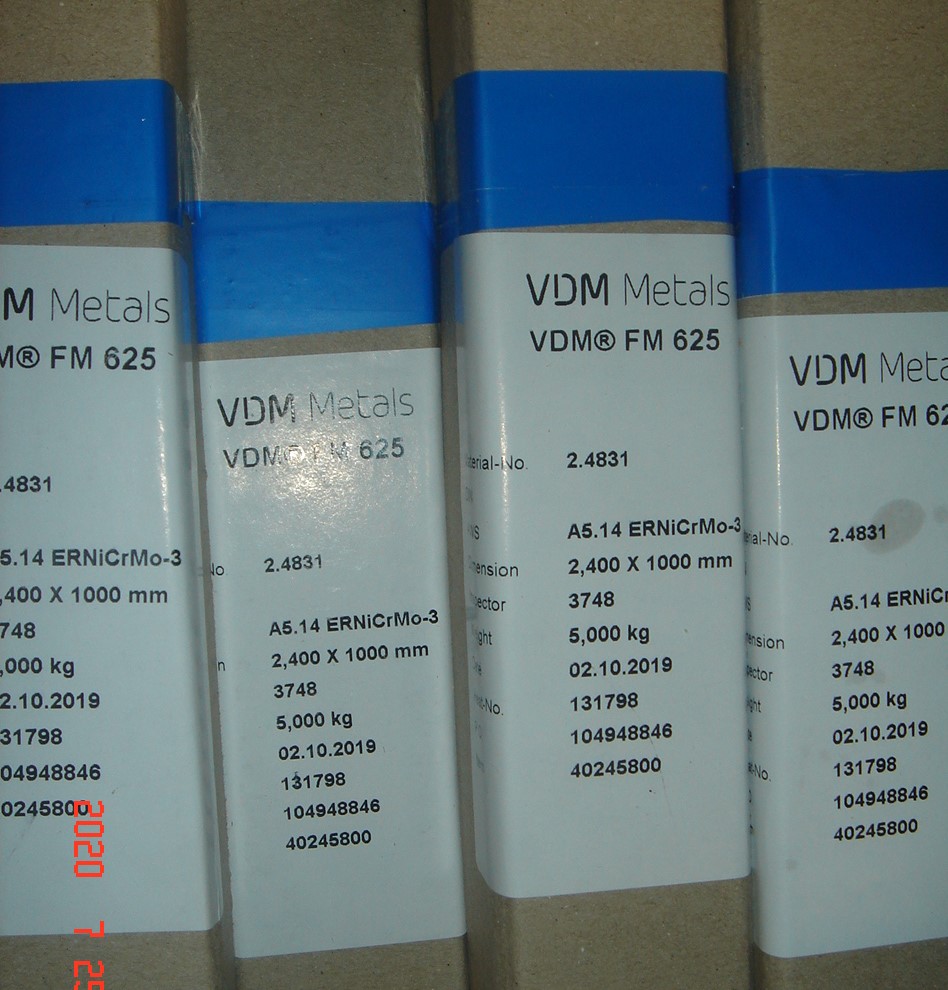

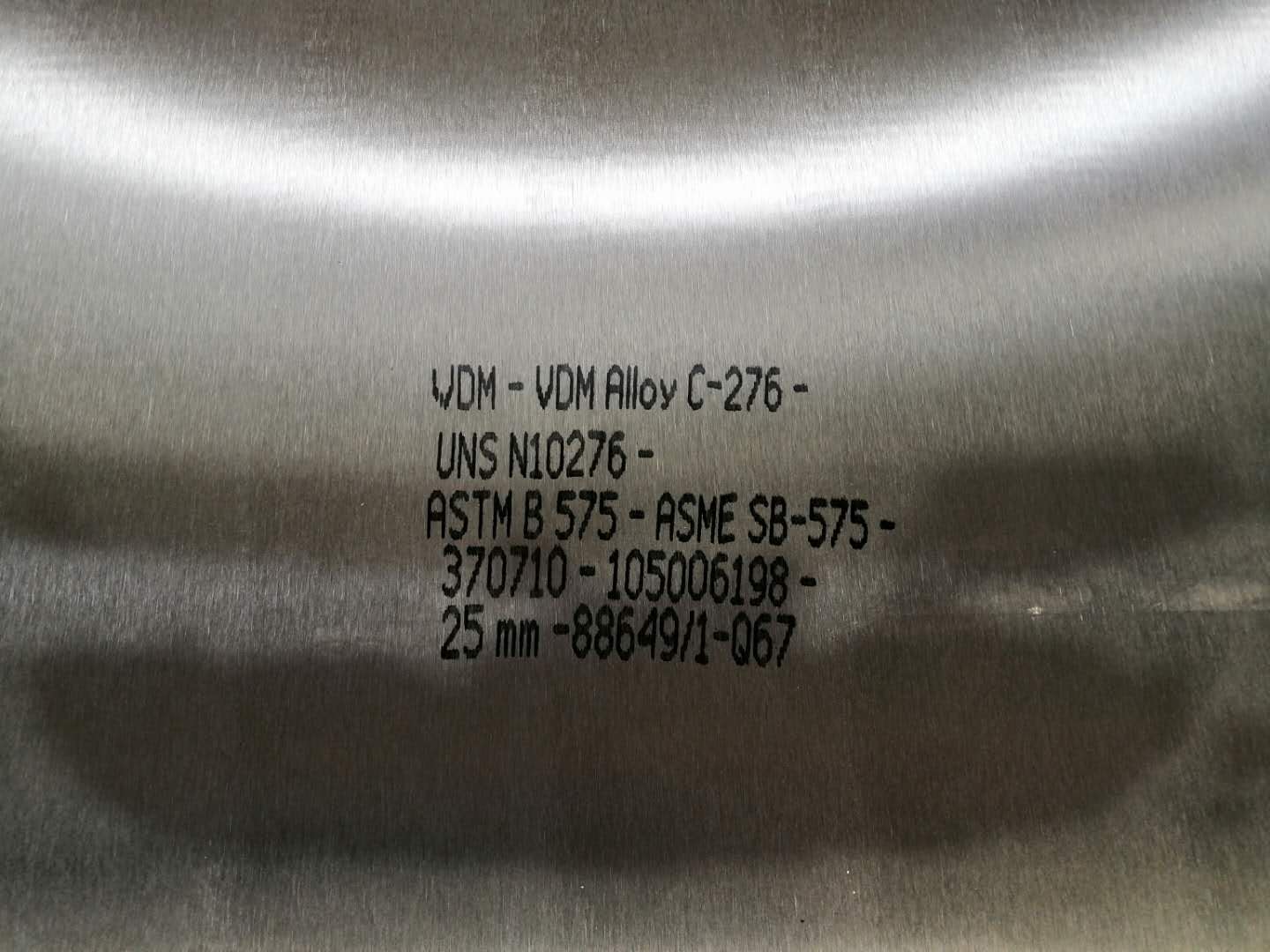

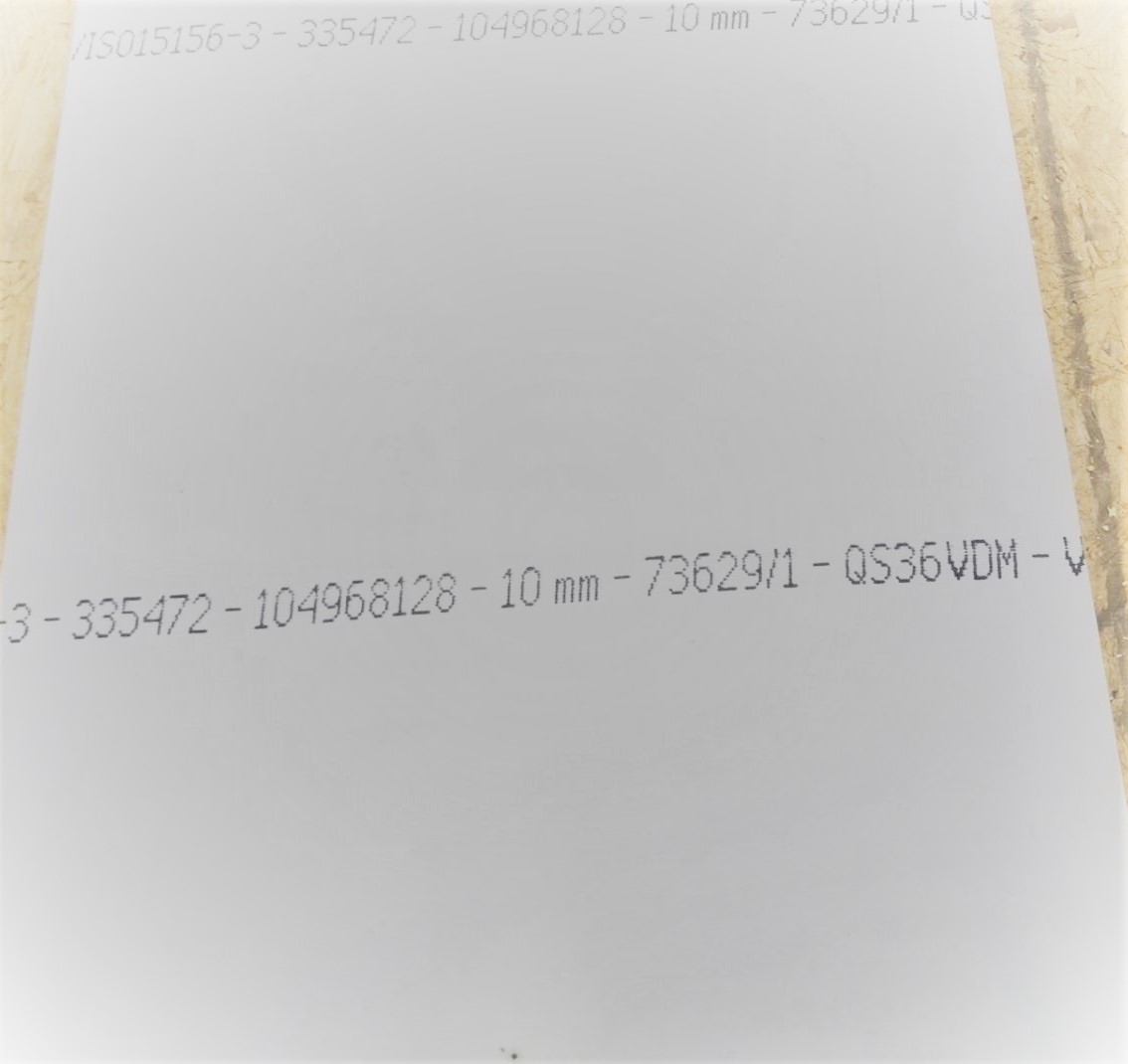

Author:格瑞新金属 Date:2025-04-09 Browse Volume:206 timesNickel-based alloys (such as Incoloy 825, Inconel 625, and Hastelloy C276), with their excellent high-temperature resistance and corrosion resistance, play a crucial and significant role in the applications of fields such as aerospace, chemical engineering, and nuclear power. Today, let's have a discussion together about the carbon emission reduction and sustainable development in the nickel-based alloy industry. The service life of nickel-based alloys in extreme environments is far longer than that of ordinary steel. Their high-temperature stability promotes the efficient operation of energy equipment. In scenarios such as the chemical industry and gas turbines, nickel-based alloys can also reduce pollution emissions and provide key material support in the field of green technologies. In the hydrogen energy industry, the nickel-based catalysts (such as Ni-Mo alloys) in water electrolysis hydrogen production equipment are more efficient and less costly than platinum-based materials. When it comes to the storage and transportation of hydrogen, high-pressure tanks made of nickel-based alloys like Incoloy 825 are capable of withstanding high pressure and have a significant weight reduction. In solar thermal power plants, Inconel 600 alloy is used for components of heat collecting pipes and heat exchangers to ensure efficient operation. For offshore tidal energy power generation devices, Hastelloy C-22 enables the equipment to generate electricity stably in harsh marine environments, reducing the carbon emissions from offshore operation and maintenance. In the offshore wind power sector, nickel-based coatings on the tower frames extend the maintenance cycle and reduce the energy consumption during operation and maintenance. In the chemical engineering field, replacing carbon steel with Hastelloy C276 as the material for reactors can greatly extend the service life of the equipment, which not only reduces the waste of resources but also decreases the pollution caused by production interruptions. As a leading supplier of high-performance nickel-based alloys, Great Group has an in-depth understanding of the frontiers of material technology. By taking advantage of its excellent corrosion resistance, high-temperature stability, and lightweight characteristics, it has become an "invisible pillar" of carbon reduction technologies, driving the global green transformation.