Solution Annealing of Nickel - based Alloys

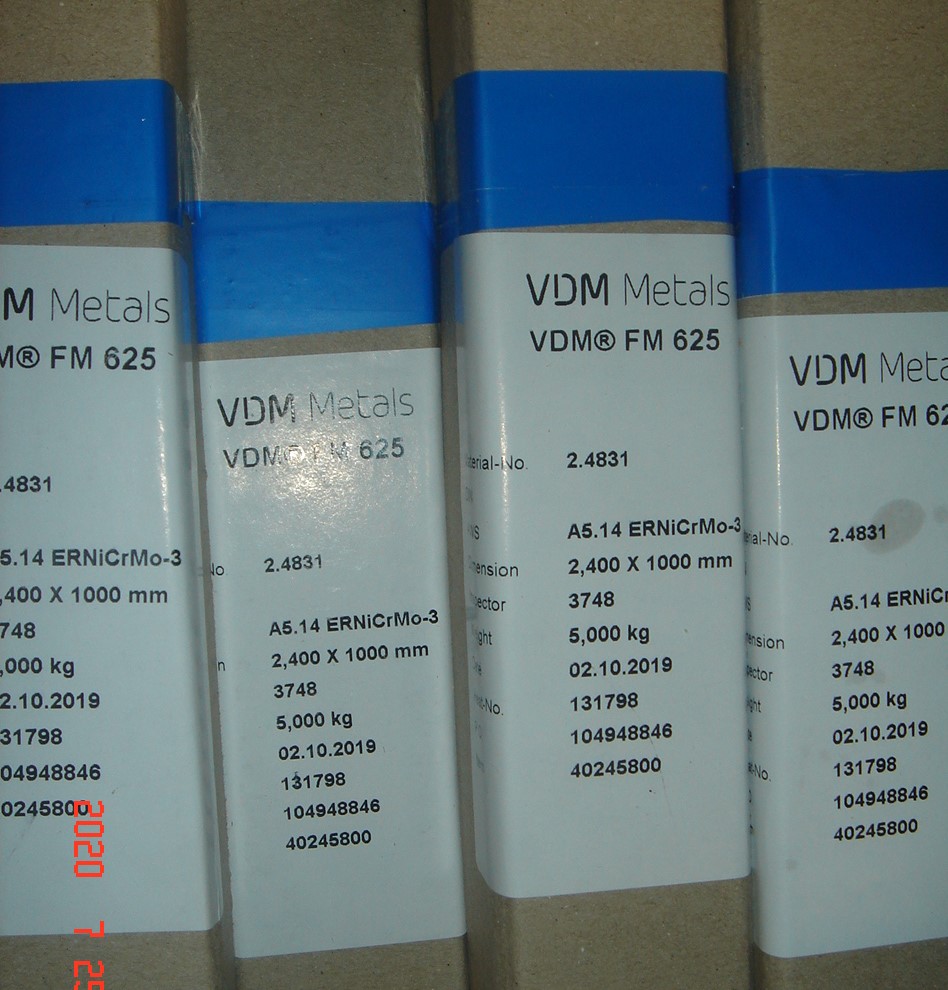

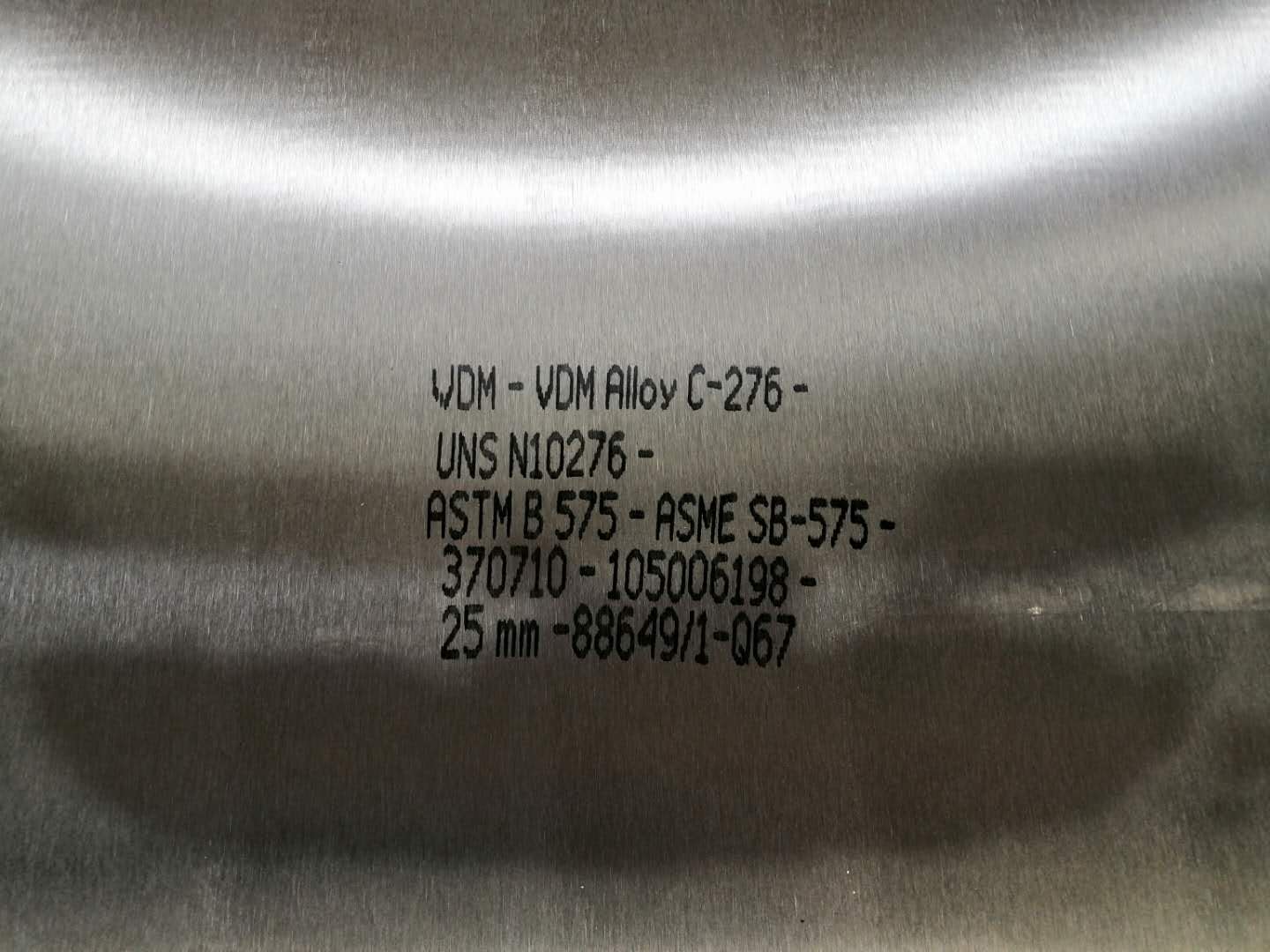

Author:走进特钢 Date:2024-10-25 Browse Volume:102 timesSolution Annealing of Nickel - based Alloys Solution Annealing Solution annealing is an important heat - treatment process. Customers often inquire whether our nickel - based alloys are in the solution - annealed state. Here, we would like to clarify that all of our imported nickel - based alloy materials are delivered in the solution - annealed state. Concept Solution annealing involves heating nickel - based alloys or stainless steels to an appropriate high temperature. This enables various alloying elements in the alloy to fully dissolve in the matrix, forming a uniform solid solution. Then, it is rapidly cooled, usually by water cooling or air cooling, to maintain this uniform solid - solution state. Functions of Solution Annealing ### Improving the Toughness of the Alloy Nickel - based alloys may have composition segregation and non - uniform microstructures in the as - cast or processed states. Solution annealing can eliminate these unfavorable factors, refine the grain size, and make the alloy's microstructure more uniform. As a result, it significantly enhances the alloy's toughness and reduces its brittleness. Enhancing Corrosion Resistance Through solution annealing, alloying elements are evenly distributed, which is conducive to the formation of a stable and dense passive film. For example, chromium plays a crucial role in the corrosion resistance of nickel - based alloys. After solution annealing, chromium can function more effectively, resisting the erosion of corrosive media. This allows the alloy to maintain good corrosion resistance in various corrosive environments, such as acidic, alkaline, or chloride - containing ones. Stabilizing the Dimensions of the Alloy It reduces the dimensional changes of the alloy during subsequent processing and use. Since solution annealing homogenizes the alloy's internal structure, it effectively reduces residual stress and prevents the alloy from deforming due to stress release during use. Process Parameters Heating Temperature The temperature range varies depending on the alloy composition. Generally, the heating temperature is typically between 1000 - 1200°C. Different grades of nickel - based alloys need to determine the optimal heating temperature according to the characteristics of their alloy compositions. For instance, for Inconel 625 alloy, the heating temperature may be around 1090 - 1200°C. Holding Time The length of the holding time mainly depends on factors such as the size, shape of the workpiece, and the furnace charge. Usually, the holding time is about several hours to ensure that the alloying elements are fully dissolved. For large - sized or complex - shaped workpieces, the holding time may be longer. Cooling Rate The cooling rate needs to be fast enough to prevent the alloying elements from precipitating again and to maintain a uniform solid - solution state. Generally, water cooling or air cooling methods are adopted. Water cooling is faster and can better suppress the precipitation of alloying elements. However, for some workpieces with complex shapes, thermal stress may cause deformation. In such cases, a milder cooling method such as air cooling can be used. Application Scenarios In the Aerospace Field Nickel - based alloys are used to manufacture key components such as engine blades. These components need to withstand high - temperature, high - pressure, and complex stress environments. Solution - annealed nickel - based alloys can provide good mechanical properties and corrosion resistance, ensuring the reliability of components under extreme conditions. In the Chemical Industry They are used to manufacture equipment such as reaction kettles and pipelines. These equipment often come into contact with various corrosive chemical substances. Nickel - based alloys that have undergone solution annealing can resist corrosion and extend the service life of the equipment.

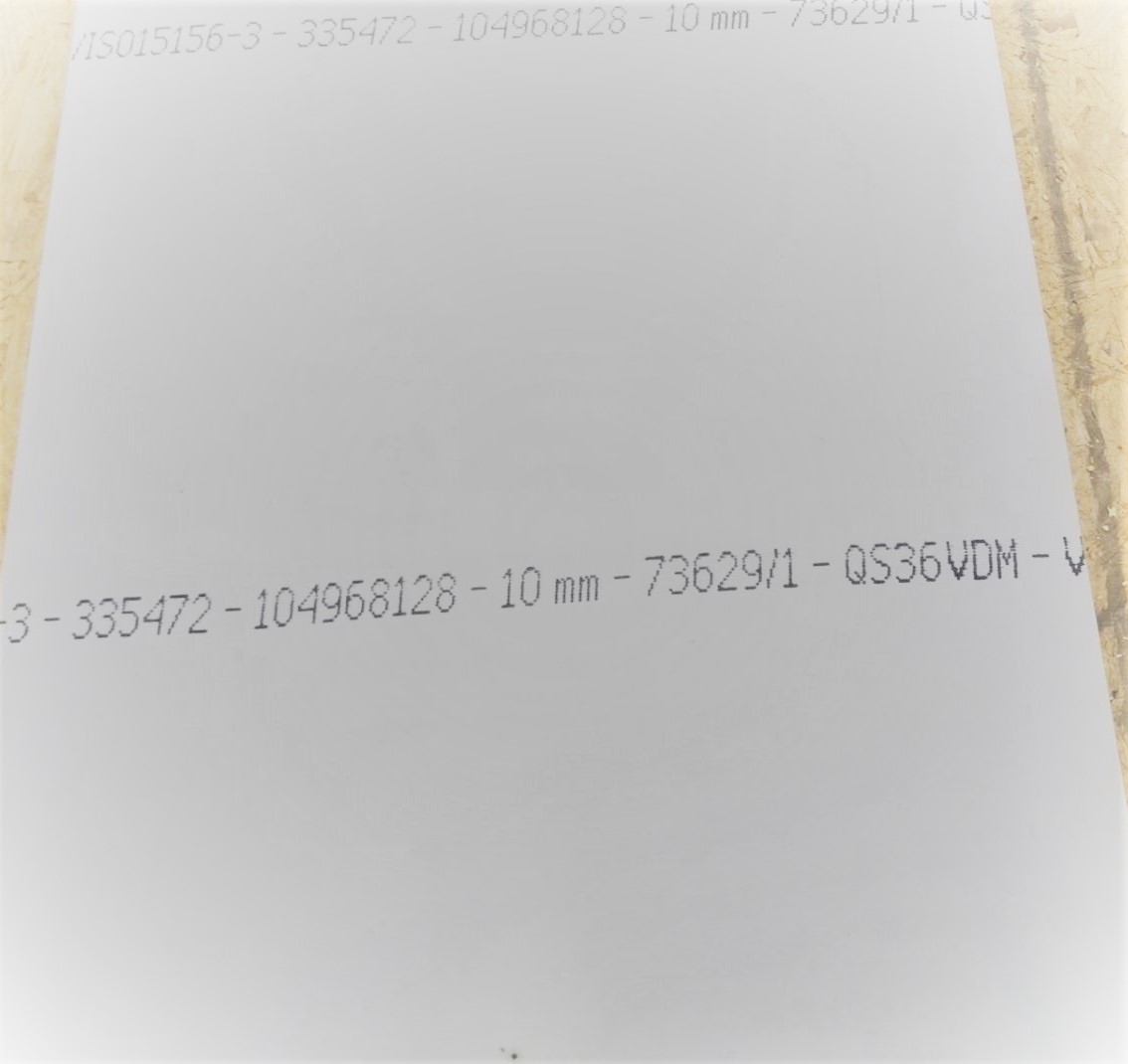

The differences between genuine imported products and domestically produced narrow metal-rolled strips.

Next:Application of Titanium Spiral Plate Heat Exchanger in Epoxy Plant