Key Points for the Precise Selection of Nickel-based Alloys

Author:走进特钢 Date:2025-03-07 Browse Volume:157 timesOn the grand stage of industry, nickel-based alloys are like a group of "superheroes" with unique skills. With their outstanding characteristics such as excellent high-temperature resistance, corrosion resistance, and high strength, they often turn the tide at crucial moments. However, faced with a wide variety of nickel-based alloys, how to select them precisely has become a difficult problem puzzling engineers. Today, this selection guide is hoped to be helpful to you.

Insight into the Source of the "Superpowers" of Nickel-based Alloys The reason why nickel-based alloys are outstanding lies in their unique chemical compositions at the core. Nickel, as the matrix element, endows the alloy with good toughness, ductility, and a certain degree of corrosion resistance, laying the foundation for subsequent alloying. The addition of chromium element is to create an "antioxidant shield". In a high-temperature and oxygen-rich environment, a dense chromium oxide film is rapidly formed to block the further intrusion of oxygen, ensuring that the material will not be easily oxidized under extremely hot working conditions. Elements such as molybdenum and tungsten are like "anti-corrosion vanguards". For strong corrosive media such as reducing agents and those containing chlorine, they greatly improve the corrosion resistance threshold of the alloy, effectively combating stubborn problems such as pitting corrosion and crevice corrosion. In addition, elements such as niobium and titanium are used to strengthen the microstructure of the alloy and enhance its high-temperature strength, enabling it to still maintain structural stability and not undergo softening and deformation under extremely high temperatures.

2. Strategies for Dealing with Corrosive Working Conditions

1. Corrosion by Strong Acids

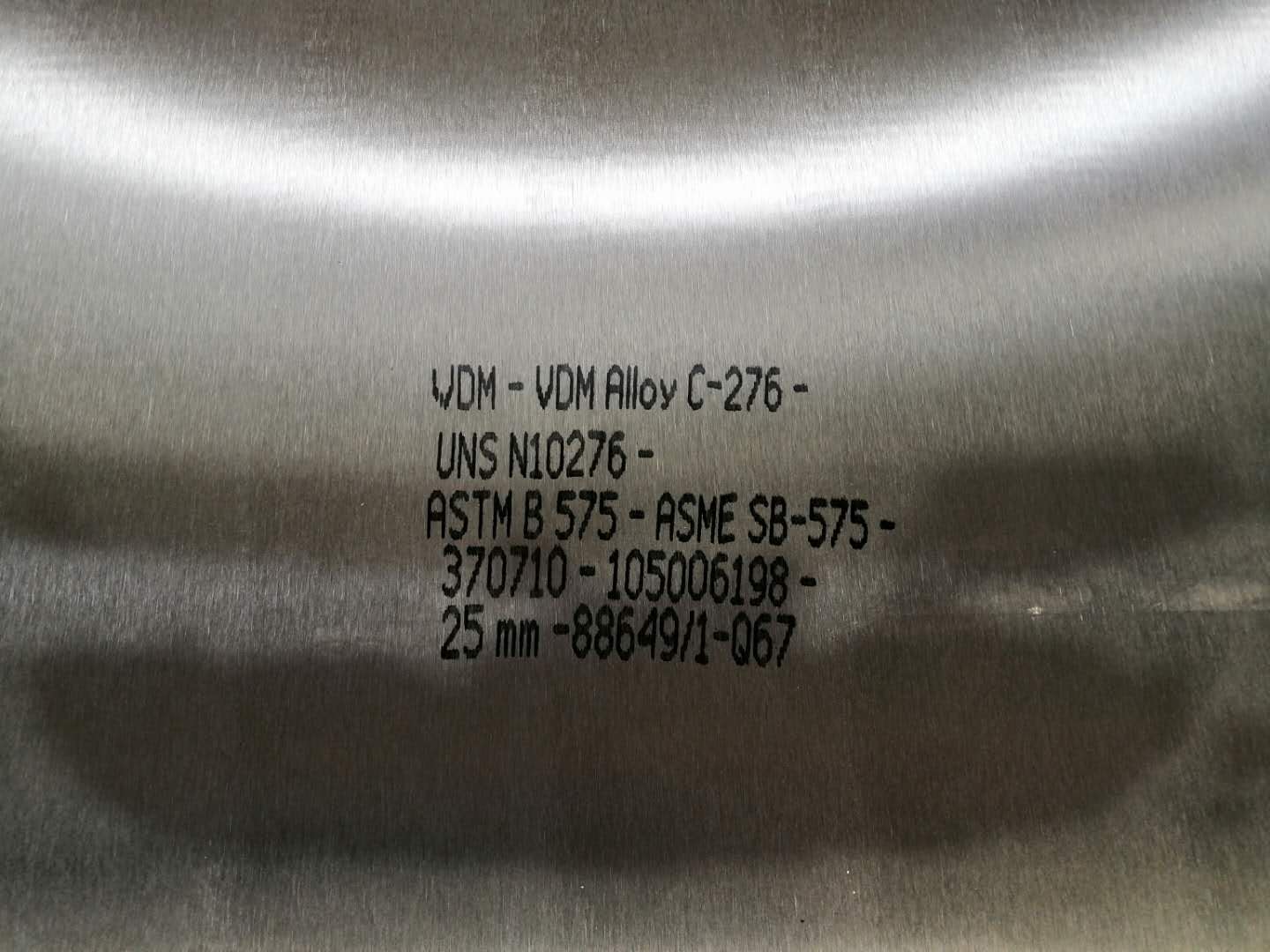

In chemical production, when facing a high-concentration hydrochloric acid environment, Hastelloy C-276 is the top choice. It contains approximately 57% nickel, 15.5% chromium, 16% molybdenum and other components. The molybdenum element has an extremely strong "sealing" ability against chloride ions, effectively preventing the erosion of the material by hydrochloric acid, ensuring the normal operation of equipment such as reactors and pipelines, and reducing the frequency of equipment maintenance.

For the corrosion environment dominated by sulfuric acid, such as sulfuric acid production units, Incoloy 825 can take on the heavy responsibility. It contains appropriate amounts of chromium, molybdenum, and copper elements. Chromium and molybdenum resist the corrosion of sulfuric acid, and copper helps to enhance the corrosion resistance. It performs stably in medium and low-concentration sulfuric acid media, reducing the damage of sulfuric acid to equipment and ensuring the continuity of production.

2. Corrosion by Strong Bases

In the alkaline cooking and dyeing processes in industries such as papermaking and textiles, Monel 400 has obvious advantages. Its composition combination of approximately 63% nickel and 30% copper has good tolerance to strong alkalis such as sodium hydroxide. The cooking pots and dyeing equipment components made of it can serve for a long time in a strong alkaline environment, reducing the cost for enterprises to replace equipment.

3. Seawater Corrosion

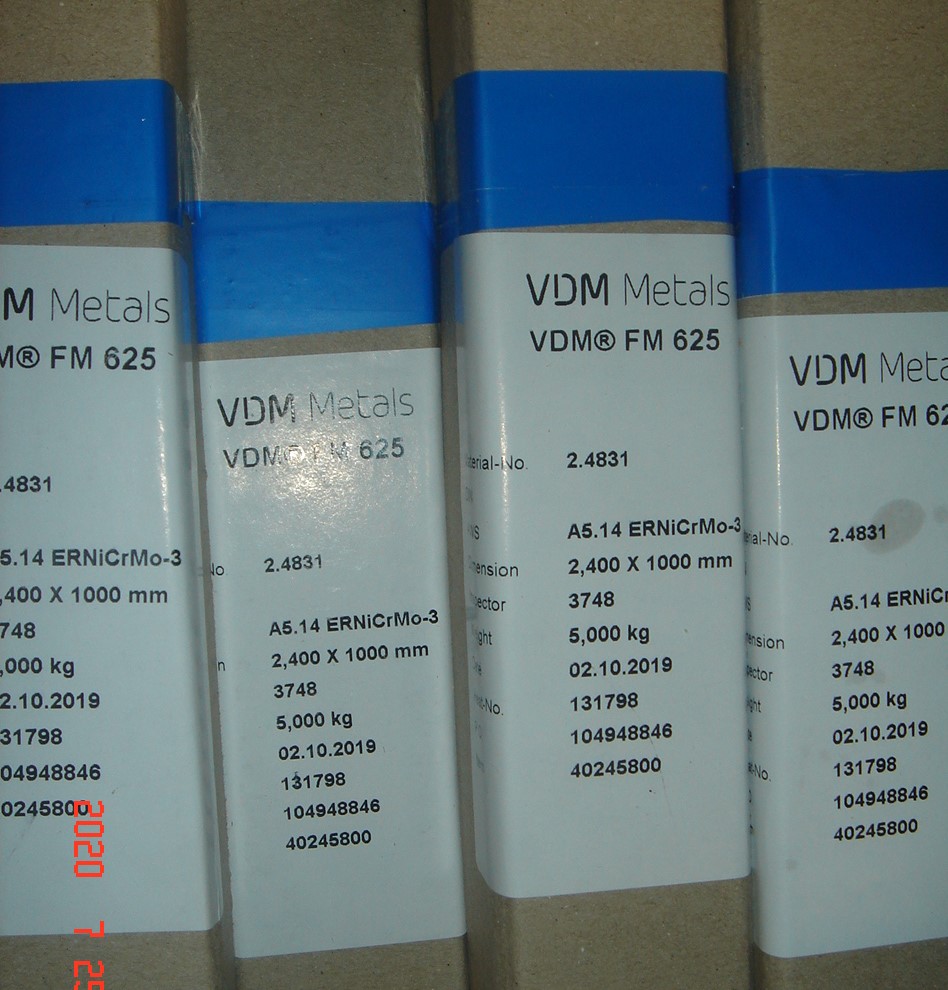

For the seawater cooling systems of ships and the underwater facilities of ocean engineering, Inconel 625 and Monel 400 each have their own merits. Inconel 625 resists seawater corrosion and erosion with its high chromium and molybdenum content, and is especially suitable for areas with fast seawater flow rates and high sediment contents. Monel 400, with the characteristics of a nickel-copper alloy, effectively prevents the attachment of marine organisms and reduces biological fouling corrosion. The combination of the two can comprehensively ensure the safe operation of marine equipment.

3. Considerations for Bearing Heavy Loads 1. Static Heavy Loads When used as high-strength bolts for large bridges, Inconel 718 stands out due to its ultra-high yield strength and good fatigue resistance. Under the combined action of static and dynamic loads such as the self-weight of the bridge and the driving of vehicles, it ensures that the bolts do not loosen or break, providing key support for the structural stability of the bridge. For the key supporting components of heavy machinery, such as the chassis of mining excavators, Inconel 625, with its high strength and certain toughness, can withstand huge working pressures and impacts, ensuring the reliable operation of the machinery and reducing the downtime due to failures. 2. Dynamic Impact Inconel X-750 performs remarkably well in the valve springs of automobile engines. It obtains a high elastic limit through age hardening. Under the high-speed dynamic impacts of the frequent opening and closing of the valves, it maintains the elasticity of the spring, ensuring smooth intake and exhaust of the engine and improving fuel efficiency.

The differences between genuine imported products and domestically produced narrow metal-rolled strips.

Next:Applications of 825 Material in the Oil and Gas Industry