Application of N06625 in aerospace

Author: Date:2024-11-29 Browse Volume:103 timesDuring the recent Zhuhai Airshow, a dazzling event in the global aerospace field, aerospace technologies and products shone brightly like stars, capturing the attention of the world. This is not only a stage for various countries to showcase their advanced military equipment and aerospace achievements, but also an excellent platform for enterprises to promote cutting-edge products and exchange innovative technologies. Taking this opportunity, I am eager to introduce to you an outstanding product that has attracted much attention — N06625. In the aerospace field, the N06625 alloy (Inconel 625, a nickel-chromium-iron alloy) plays a crucial role with its excellent characteristics. The aircraft engine, known as the "heart" of an airplane, faces extreme working conditions such as high temperature, high pressure, and high stress. The N06625 alloy is often used to manufacture key components of the engine, such as turbine discs, blades, and combustion chambers. The turbine disc bears huge centrifugal force and the impact of high-temperature gas during high-speed rotation. The high strength and high-temperature resistance of the N06625 alloy can ensure the stable operation of the turbine disc in a high-temperature environment and maintain the efficient power output of the engine. The working temperature of the turbine blades is extremely high. The N06625 alloy can withstand high-temperature corrosion and thermal stress, and its good fatigue resistance can effectively resist the fatigue cracks generated by the blades under high-frequency vibration, ensuring the long-term reliable operation of the engine. The combustion chamber needs to withstand the scouring of high-temperature flames and the corrosion of gas. The high-temperature oxidation resistance and thermal corrosion resistance of the N06625 alloy make it an ideal material for manufacturing the combustion chamber, which helps to improve the combustion efficiency and engine performance. The N06625 alloy is also applied to parts such as the fuselage structure and landing gear of the aircraft. In the fuselage structure, some connecting components that bear large stress or are located in high-temperature areas, such as the frames and connectors in the high-temperature zone, are made of the N06625 alloy. Its high strength and corrosion resistance help to enhance the integrity and durability of the fuselage structure and ensure flight safety. The landing gear bears huge impact force and friction force during the takeoff and landing of the aircraft. The high strength, high toughness, and fatigue resistance of the N06625 alloy enable it to meet the performance requirements of the landing gear under complex stress conditions, ensuring that the landing gear can reliably complete the task of supporting the aircraft during takeoff and landing. Moreover, it has good corrosion resistance in harsh airport environments, extending its service life. In the fuel system and hydraulic system of aerospace, the N06625 alloy is equally indispensable. Components such as pipes, pumps, and valves in the fuel system need to be in long-term contact with various fuels and withstand certain pressure and temperature changes. The corrosion resistance of the N06625 alloy can prevent the components of the fuel system from being corroded, ensuring the stable transportation of fuel and the sealing of the system. The working pressure of the hydraulic system is relatively high, and strict requirements are imposed on the strength and sealing performance of its components. Components such as hydraulic cylinders and hydraulic pipes made of the N06625 alloy can work stably in a high-pressure environment. Its good machining performance also facilitates the manufacture of high-precision hydraulic system components, ensuring that the hydraulic system can accurately and reliably control various flight attitudes and operation actions of the aircraft. In addition, in the manufacturing of aerospace vehicles, the N06625 alloy is also used for some high-temperature structural components and connecting components. For example, in the propulsion system of a spacecraft, components such as the nozzle parts in contact with high-temperature gas and the inner lining of the engine combustion chamber are made of the N06625 alloy to adapt to the high-temperature environment and complex mechanical conditions during the launch and in-orbit operation of the spacecraft. In the external structural components of the spacecraft, such as some parts that need to withstand space environment radiation, temperature alternation, and the impact of tiny meteoroids, the comprehensive performance of the N06625 alloy can provide a strong guarantee for the structural integrity and reliability of the spacecraft, enabling it to operate stably for a long time in the harsh space environment and complete various aerospace tasks. In conclusion, the widespread application of the N06625 alloy in the aerospace field plays a crucial role in improving the performance of aircraft, ensuring flight safety, and promoting the development of aerospace technology. As one of the main grades of Great Group, the N06625 alloy has a complete range of inventory specifications. If you have any technical questions, you are welcome to call for consultation.

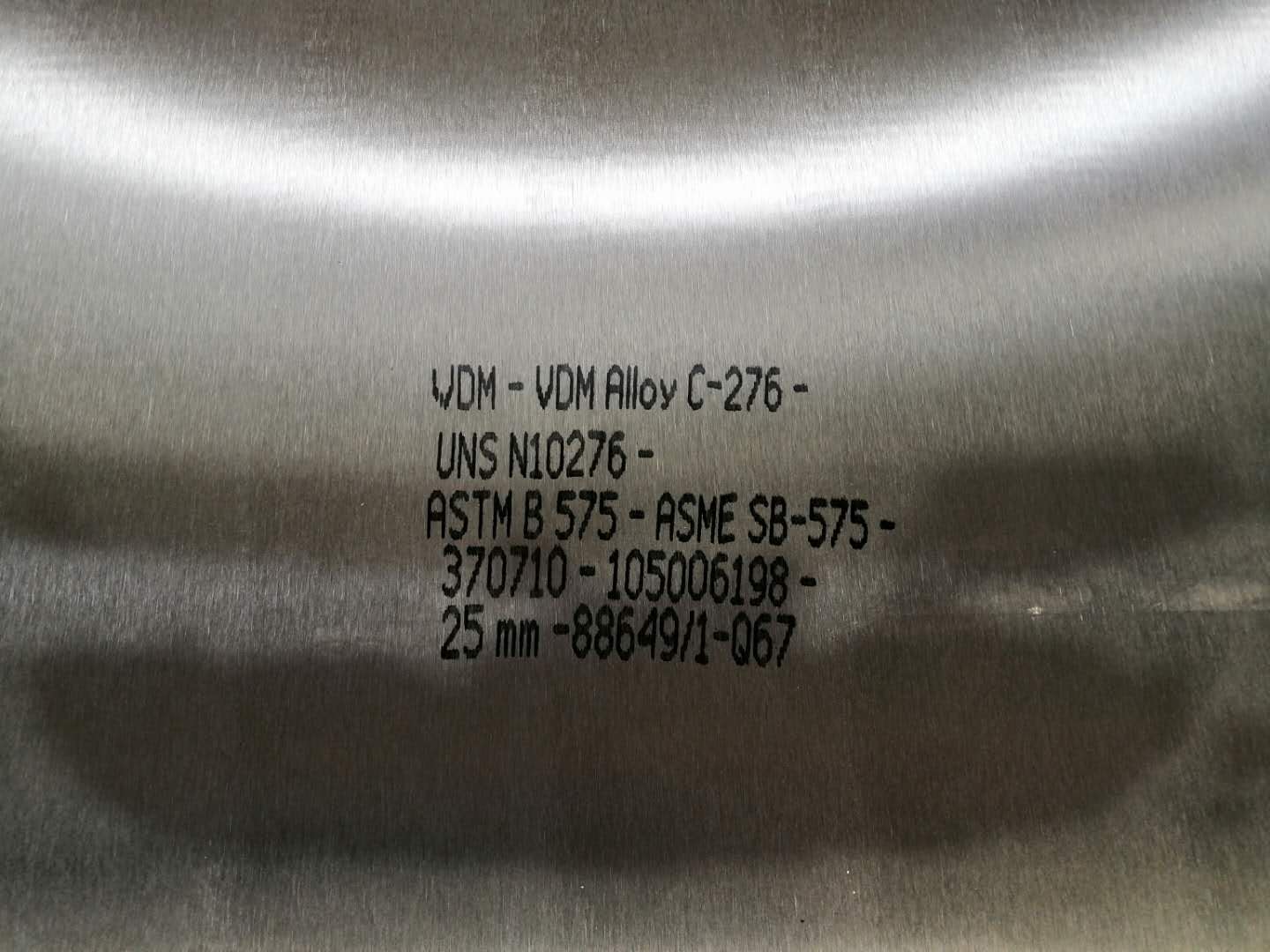

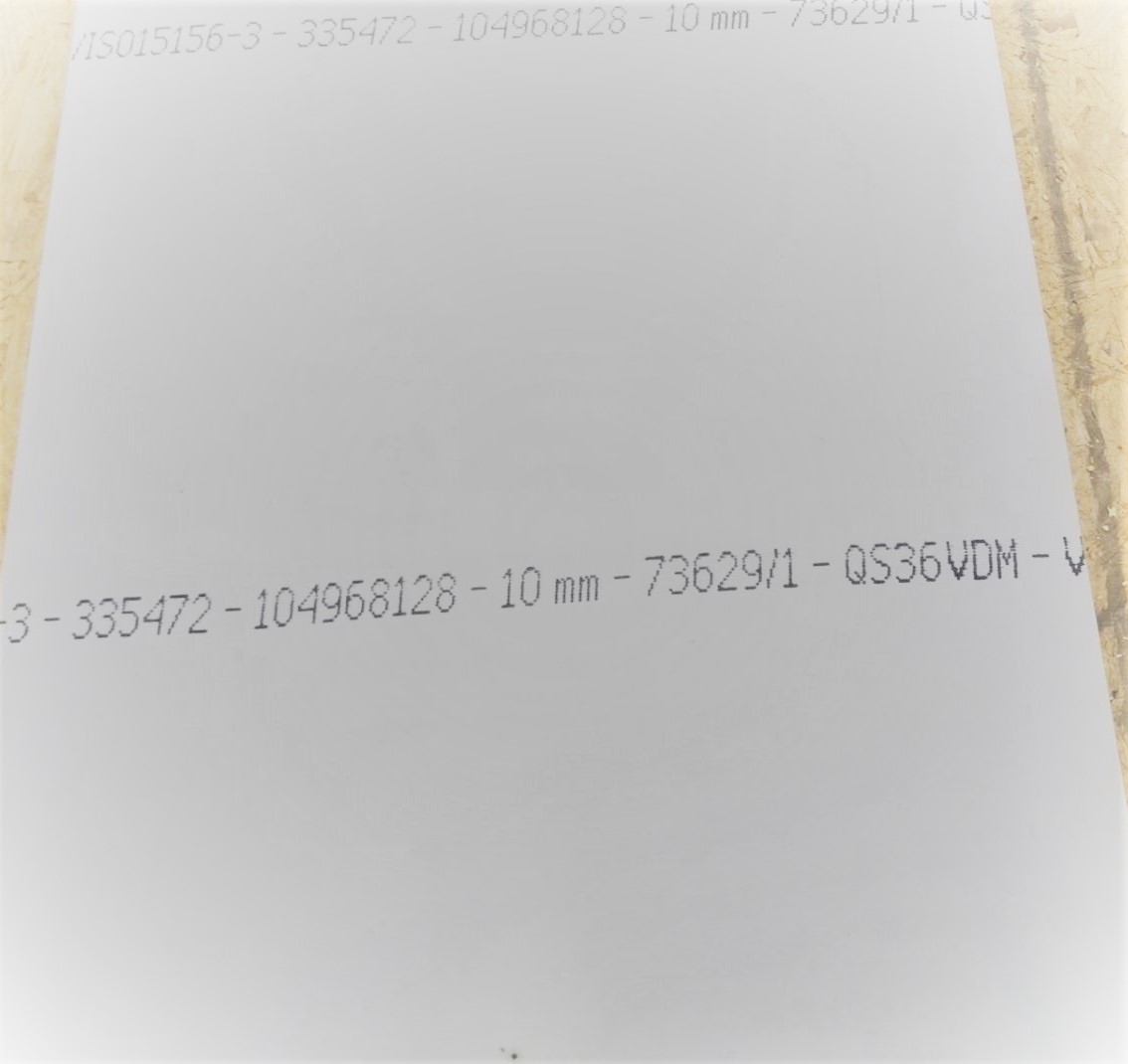

The differences between genuine imported products and domestically produced narrow metal-rolled strips.

Next:Solution Annealing of Nickel - based Alloys