The Relationship between the Residual Stress of Steel Coils and the Flatness of Coiled Materials

Author:走进特钢 Date:2025-04-11 Browse Volume:128 times### PART.01 Generation of Residual Stress During the production process of steel coils, residual stress is formed inside the steel due to processes such as rolling, cooling, and coiling. For example, different deformation degrees in various parts during rolling, uneven cooling rates, and the tension during coiling can all lead to the generation of residual stress. - **Non - uniform plastic deformation**: In metal processing such as rolling and forging, the deformation degree varies in different parts of the workpiece, resulting in internal residual stress. Take rolling as an example. The deformation amount of the surface and the core of the rolled piece is different. The surface deforms more while the core deforms less. After rolling, residual stress is generated due to the inconsistent deformation between the surface and the core. - **Thermal effect**: In thermal processing such as heat treatment and welding, the workpiece goes through heating and cooling processes. Due to the inconsistent thermal expansion and contraction in different parts, thermal stress is generated, which becomes residual stress after cooling. For instance, during welding, the weld and its adjacent areas expand due to heat, while the areas far from the weld have a lower temperature and less expansion. When cooling, the contraction of the weld area is restricted by the surrounding materials, resulting in residual tensile stress. - **Microstructure transformation**: Metal may undergo microstructure transformation during heating and cooling, and different microstructures have different specific volumes. For example, when steel is quenched, it transforms from austenite to martensite. The specific volume of martensite is larger than that of austenite. The volume change caused by this microstructure transformation is hindered by the surrounding structure, thus generating residual stress. - **Machining**: During the cutting process, the cutting force between the tool and the workpiece causes plastic deformation on the surface layer of the workpiece. The internal material restricts the deformation of the surface layer, resulting in residual stress on the surface and inside the workpiece. In addition, in the grinding process, the grinding heat also leads to the generation of thermal stress and microstructure stress on the workpiece surface, further forming residual stress. - **Assembly stress**: In the mechanical assembly process, factors such as the interference fit of parts and the assembly sequence may also lead to the generation of residual stress. For example, when assembling parts with an interference fit, the extrusion of the mating surface causes residual stress inside the parts. ### PART.02 Influence of Residual Stress on the Flatness of Coiled Materials - **Causing coiled material warping**: When there is residual stress inside the steel coil, these stresses tend to be released after the coil is unrolled, leading to the deformation of the coiled material. If the residual stress is unevenly distributed, local warping may occur on the coiled material, affecting its flatness. For example, in the width direction, if the residual compressive stress on one side is larger and the residual tensile stress on the other side is larger, the coiled material will bend towards the side with compressive stress, forming a wavy unevenness. - **Resulting in wavy undulations of the coiled material**: The presence of residual stress may also cause wavy undulations in the length direction of the coiled material. This is because the stress inside the coiled material is unbalanced. During the process of trying to reach a balanced state, the coiled material undergoes local stretching or compression, thus forming waves. These wavy undulations not only affect the appearance quality of the coiled material but also have an adverse impact on subsequent processing and use. - **Leading to uneven edges of the coiled material**: The residual stress at the edges of the steel coil is usually complex, and stress concentration is likely to occur. This may cause the edges of the coiled material to curl or twist, making the edges uneven and affecting the flatness and dimensional accuracy of the coiled material. In actual production, defects such as "fluted edges" or "camber" are often observed at the edges of the coiled material, which are largely related to the uneven distribution of residual stress. ### PART.03 Methods to Control Residual Stress to Improve the Flatness of Coiled Materials - **Optimizing the rolling process**: By reasonably adjusting parameters such as rolling temperature, reduction, and rolling speed, the steel can be deformed as uniformly as possible during rolling, reducing the generation of residual stress. For example, using a multi - pass rolling method with small reduction can make the stress distribution inside the steel more uniform. - **Improving the cooling process**: Controlling the cooling speed and uniformity is an important measure to reduce residual stress. For example, using equipment and processes for uniform cooling can avoid stress concentration caused by too fast or too slow local cooling during the cooling process of the steel. For some steels with high flatness requirements, processes such as slow cooling or tempering can also be used to eliminate part of the residual stress. - **Adjusting the coiling process**: Reasonably controlling parameters such as coiling tension and coiling temperature can make the internal stress distribution of the steel coil reasonable during coiling. For example, according to the material and specification of the steel, selecting an appropriate coiling tension can avoid an increase in residual stress caused by excessive or insufficient tension. At the same time, appropriately performing stress relaxation treatment after coiling also helps to improve the flatness of the coiled material.

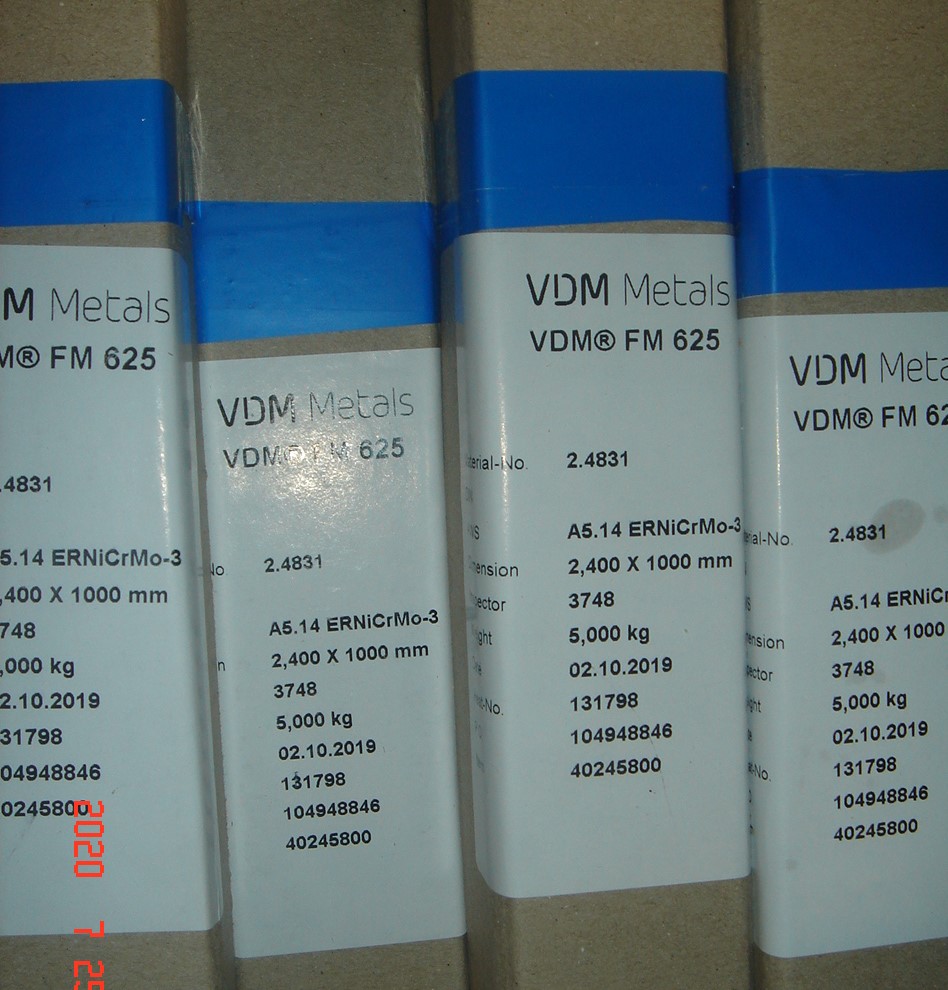

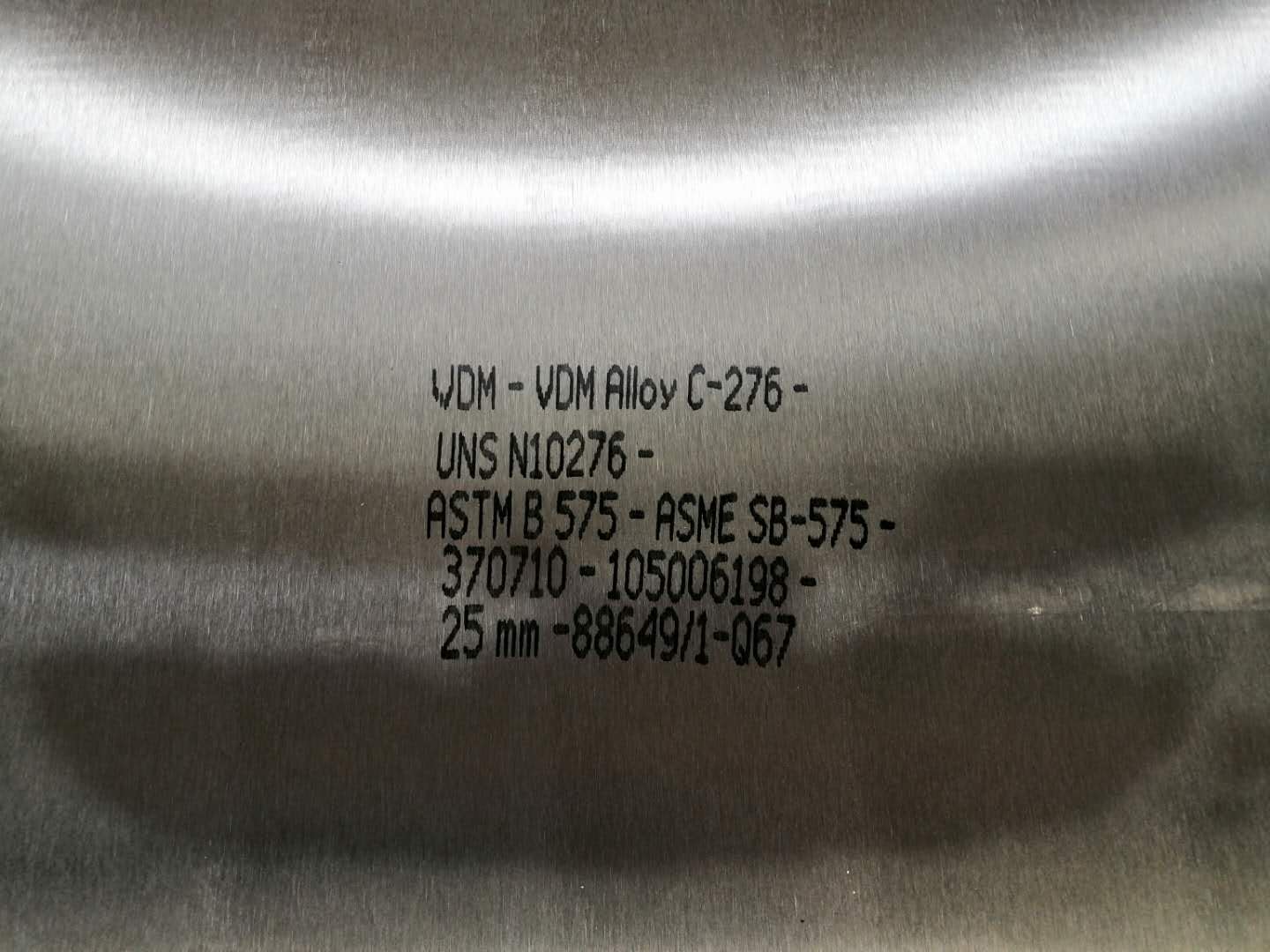

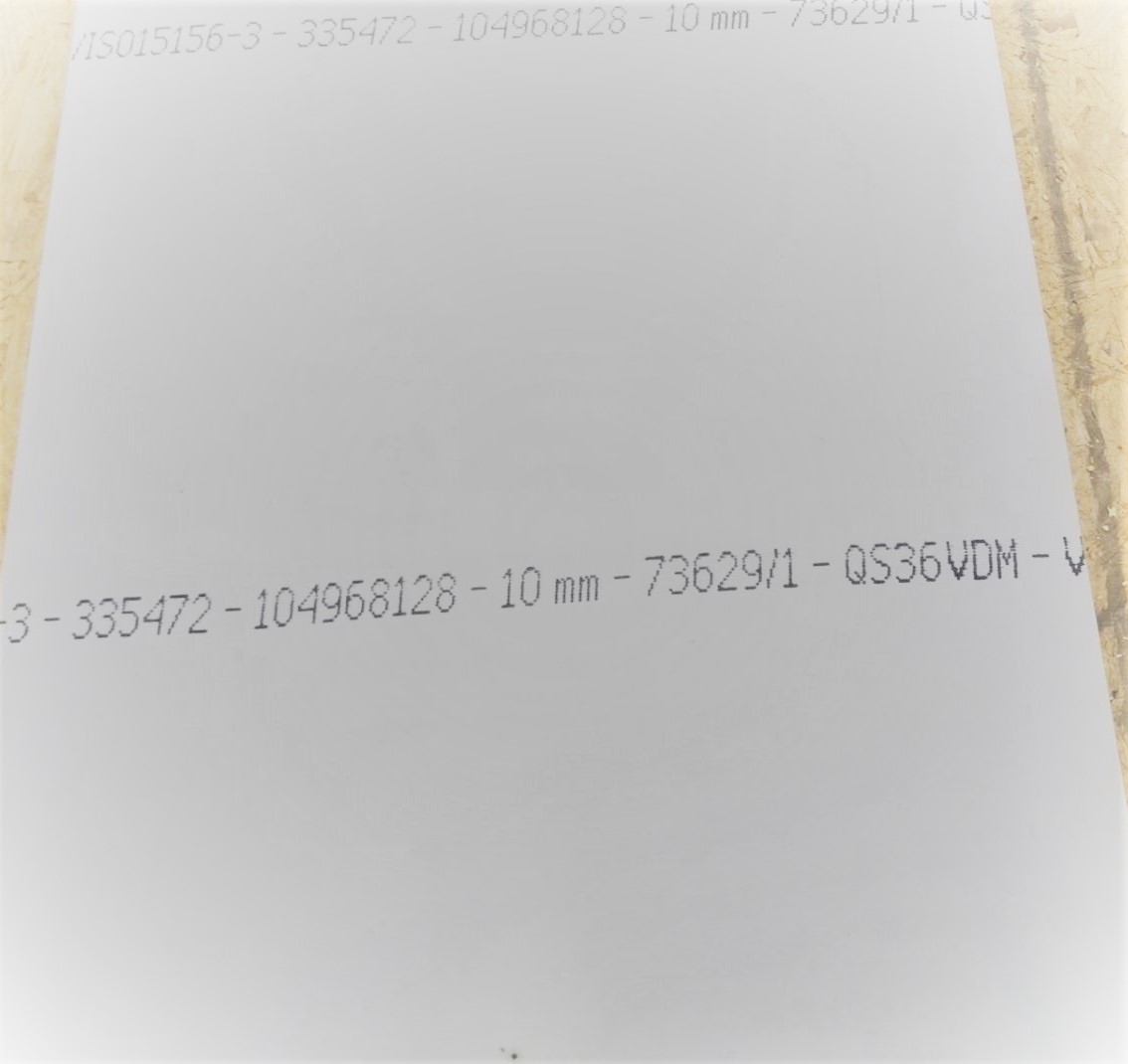

The differences between genuine imported products and domestically produced narrow metal-rolled strips.

Next:Understand SSCC: sulfide stress corrosion cracking